In the showcase section, listed are some of the recent installations. Please view the slideshow to see various components of an elevating device along with a brief description for the slide. As elevator installation is a tandem activity between the owner and elevator contractor, with preparatory work for hoistway shaft and machine room (involving various civil, electrical, mechanical & miscellaneous metal work etc.) to be provided by the owner. We have also included in the slide show, pictures showing the preparatory work to be provided by the owners’ or their agents.

Although care has been taken to include various product types in the Showcase section of this website, however feel free to Contact Us if you require any specific information on any of the elevating device from Our Products.

Typical dumbwaiter shaft consisting of masonry

blocks or steel stud, plywood & drywall construction

Typical dumbwaiter shaft consisting of masonry

blocks or steel stud, plywood & drywall construction St steel dumbwaiter, counter height loading

with landing door closed. Also shown is the controller adjacent to

the entrance.

St steel dumbwaiter, counter height loading

with landing door closed. Also shown is the controller adjacent to

the entrance.  Dumbwaiter with door in open position.

Optional shelving is available to enable multi-tier loading.

Dumbwaiter with door in open position.

Optional shelving is available to enable multi-tier loading. Access door housing the dumbwaiter machine is

shown below the sill of the bottom most level dumbwaiter entrance.

Access door housing the dumbwaiter machine is

shown below the sill of the bottom most level dumbwaiter entrance.

Typical dumbwaiter shaft with, rough wall

openings, consisting of structural wood for support & drywall

construction for fire separation.

Typical dumbwaiter shaft with, rough wall

openings, consisting of structural wood for support & drywall

construction for fire separation. St steel dumbwaiter, floor loading with 30â€

deep pit and vertical bi-parting landing door in closed position

with illuminated push button.

St steel dumbwaiter, floor loading with 30â€

deep pit and vertical bi-parting landing door in closed position

with illuminated push button.  Dumbwaiter with door in open position.

Optional shelving is available to enable multi-tier loading. Machine

housed in pit at bottom of shaft.

Dumbwaiter with door in open position.

Optional shelving is available to enable multi-tier loading. Machine

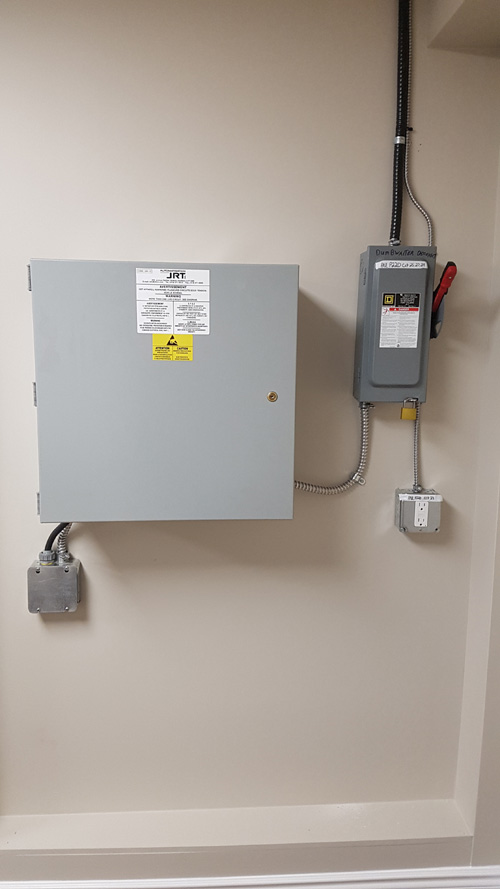

housed in pit at bottom of shaft. Controller; fused disconnect box & GFCI plug,

provided by others, at the bottom landing directly behind the

hoistway shaft.

Controller; fused disconnect box & GFCI plug,

provided by others, at the bottom landing directly behind the

hoistway shaft.  Installation of free standing structure of

the material lift and its anchoring to building members to support

the hoisting equipment, platform assembly.

Installation of free standing structure of

the material lift and its anchoring to building members to support

the hoisting equipment, platform assembly. Code allows installation of Type A (Non Rider)

material lifts in shallow pit and Type B (Rider Enabled) lifts can

even be installed with no pit depth.

Code allows installation of Type A (Non Rider)

material lifts in shallow pit and Type B (Rider Enabled) lifts can

even be installed with no pit depth.  Provided with bank of hall buttons for all

landings on every floor, for momentary touch call & send operation.

Entrances provided with vision panels.

Provided with bank of hall buttons for all

landings on every floor, for momentary touch call & send operation.

Entrances provided with vision panels. No operation buttons permitted on the car

platform for a Type A material lift. Also requires provision for car

gate and car ceiling, like a dumbwaiter.

No operation buttons permitted on the car

platform for a Type A material lift. Also requires provision for car

gate and car ceiling, like a dumbwaiter. Rider enabled, Type B, Material Lift with 454

Kg (1,000 lb) load capacity with single panel swing door. Landing

door smooth & flush from inside for rider safety.

Rider enabled, Type B, Material Lift with 454

Kg (1,000 lb) load capacity with single panel swing door. Landing

door smooth & flush from inside for rider safety. St steel walls & flooring to enable carrying

of food items in a kitchen, provided with a bank of operation

buttons and handrail on the platform for the authorized rider.

St steel walls & flooring to enable carrying

of food items in a kitchen, provided with a bank of operation

buttons and handrail on the platform for the authorized rider.

Double panel swing door enable larger platform

size and load carrying capacity up to 10,000 lb and above. Lifts

provided with cantilevered or twin cylinder design.

Double panel swing door enable larger platform

size and load carrying capacity up to 10,000 lb and above. Lifts

provided with cantilevered or twin cylinder design. Fully automated horizontal

conveyor feeds the vertical conveyor for automatic transportation of

skid between the fixed levels of a building.

Fully automated horizontal

conveyor feeds the vertical conveyor for automatic transportation of

skid between the fixed levels of a building. Vertical slide-up entrances on each landing

opens up & close automatically upon sensing the load on horizontal

conveyor.

Vertical slide-up entrances on each landing

opens up & close automatically upon sensing the load on horizontal

conveyor. With load on horizontal conveyor: Loaded and

ready to be dispatched to the level above. Suitable/ optimum

solution for heavy and continuous (not intermittent) flow of goods

in a warehouse.

With load on horizontal conveyor: Loaded and

ready to be dispatched to the level above. Suitable/ optimum

solution for heavy and continuous (not intermittent) flow of goods

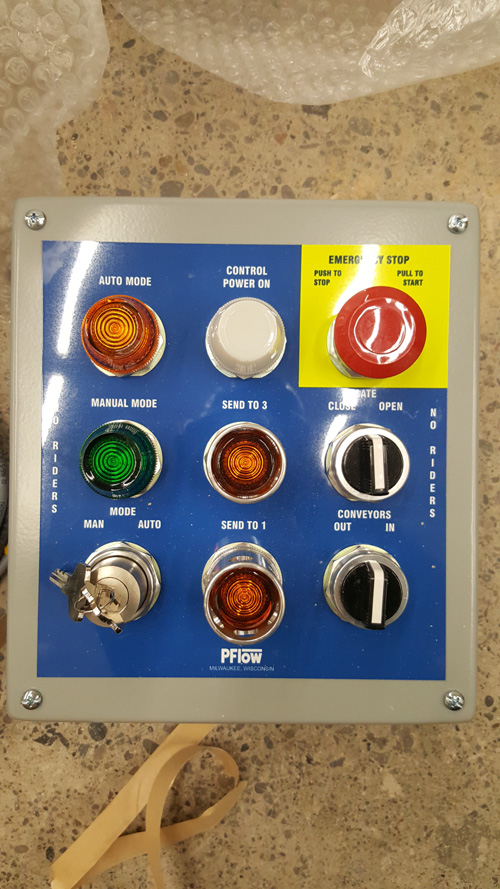

in a warehouse. Fully functional (allowing manual & auto mode

control) operation panel located on all the landings with

illuminated operation buttons and stop button.

Fully functional (allowing manual & auto mode

control) operation panel located on all the landings with

illuminated operation buttons and stop button. Freight elevator with vertical bi-parting

ready for load testing before TSSA inspection and final

commissioning.

Freight elevator with vertical bi-parting

ready for load testing before TSSA inspection and final

commissioning. Car top of the freight elevator showing Car

Top Guarding, Car Top Station, Refuge Space and Access Hatch.

Car top of the freight elevator showing Car

Top Guarding, Car Top Station, Refuge Space and Access Hatch. Showing the joined sections of the underside

of elevator platform, non-buried cylinders, bottom sling assembly &

apron.

Showing the joined sections of the underside

of elevator platform, non-buried cylinders, bottom sling assembly &

apron. Guarded pit lighting (by others), Guide

rails, Twin cylinder design with piping, valves & means of oil

collection. Spring buffers.

Guarded pit lighting (by others), Guide

rails, Twin cylinder design with piping, valves & means of oil

collection. Spring buffers. Vertical transportation of a skid of raw food

material to a working platform above with the help of hydraulic

cylinder and chain assembly. Power unit placed adjacent to the shaft

at bottom.

Vertical transportation of a skid of raw food

material to a working platform above with the help of hydraulic

cylinder and chain assembly. Power unit placed adjacent to the shaft

at bottom. Vertical slide-up gates for guarding of

entrances at top & bottom. Free standing structure of lift is fully

enclosed with solid St steel panel sheets. Controller mounted on the

hoistway structure.

Vertical slide-up gates for guarding of

entrances at top & bottom. Free standing structure of lift is fully

enclosed with solid St steel panel sheets. Controller mounted on the

hoistway structure. A turn table mounted on the carriage of this

device facilitates turning of the skid for easy offloading of the

food bags at the working platform above.

A turn table mounted on the carriage of this

device facilitates turning of the skid for easy offloading of the

food bags at the working platform above. Being a food processing plant, equipment

subject to frequent & periodic washing & cleaning.

Being a food processing plant, equipment

subject to frequent & periodic washing & cleaning. Fire rated, Vertical Bi-Parting entrance with

bank of Hall Buttons & DI (direction indicator)

Fire rated, Vertical Bi-Parting entrance with

bank of Hall Buttons & DI (direction indicator) Class B Loading elevator cab to suit

transportation of automobiles in a car dealership

Class B Loading elevator cab to suit

transportation of automobiles in a car dealership Fully functional car operating panel (COP)

with fire fighters’ service panel for phase 2 recall

Fully functional car operating panel (COP)

with fire fighters’ service panel for phase 2 recall Non-buried, directly coupled, twin cylinder

and crosshead assembly for vertical movement of the elevator cab

Non-buried, directly coupled, twin cylinder

and crosshead assembly for vertical movement of the elevator cab

2 bay 3 tier stacker to enable parking of 6

vehicles

2 bay 3 tier stacker to enable parking of 6

vehicles 1 hydraulic power unit with wall mounted

controller to support the multi stacker system

1 hydraulic power unit with wall mounted

controller to support the multi stacker system Aluminum grating platform for strength with

slopping threshold for easy movement of vehicles

Aluminum grating platform for strength with

slopping threshold for easy movement of vehicles Gates with locking arrangement as required by

TSSA (Authority Having Jurisdiction)

Gates with locking arrangement as required by

TSSA (Authority Having Jurisdiction) Hoist & platform assembly for vertical

movement of automobiles between the storage levels

Hoist & platform assembly for vertical

movement of automobiles between the storage levels Overhead geared motor and chain hist assembly

supported by I beams anchored to the building structural members

Overhead geared motor and chain hist assembly

supported by I beams anchored to the building structural members

Rotating pallet in front of the vertical hoist

opening, on every floor, to dispatch the automobile to a particular

gallery

Rotating pallet in front of the vertical hoist

opening, on every floor, to dispatch the automobile to a particular

gallery Typical automobile conveyors on every floor

for horizontal movement & storage of vehicles

Typical automobile conveyors on every floor

for horizontal movement & storage of vehicles Passenger Elevator with St Steel Entrances

Passenger Elevator with St Steel Entrances

Car Operating Panel (COP) with Fire Fighters’

Operation for Phase 2 recall

Car Operating Panel (COP) with Fire Fighters’

Operation for Phase 2 recall Contacts for Fire Alarm Signal and Air

Conditioning in the machine room, provided by Others

Contacts for Fire Alarm Signal and Air

Conditioning in the machine room, provided by Others Fused disconnect boxes with GFCI plug

provided by others

Fused disconnect boxes with GFCI plug

provided by others LULA Elevator with 2-Speed sliding entrances

LULA Elevator with 2-Speed sliding entrances

LULA Elevator cab in raised plastic laminate

panel and Car Operating Panel (COP) in St Steel

LULA Elevator cab in raised plastic laminate

panel and Car Operating Panel (COP) in St Steel Non buried cantilevered roped cylinder design

Non buried cantilevered roped cylinder design

Power unit with submersible pump and Blaine

control valves

Power unit with submersible pump and Blaine

control valves Hollow metal, fire rated, Swing door

Hollow metal, fire rated, Swing door Entrance provided with keyed (for restricted

access) constant pressure operation pushbutton with in use light

Entrance provided with keyed (for restricted

access) constant pressure operation pushbutton with in use light

Enclosed cab with non slip rubber flooring

Enclosed cab with non slip rubber flooring

Laminate/ melamine cab provided with keyed

(for restricted access) constant pressure operation pushbutton and

handrail

Laminate/ melamine cab provided with keyed

(for restricted access) constant pressure operation pushbutton and

handrail Before the installation

Before the installation Provided with metal & glass hoistway enclosure

exposed to elements of weather

Provided with metal & glass hoistway enclosure

exposed to elements of weather Metal & glass enclosure anchored to a concrete

pad

Metal & glass enclosure anchored to a concrete

pad Lift cab with right angle entrance opening

into the building

Lift cab with right angle entrance opening

into the building Custom size dumbwaiter was designed to suit an

existing 4 stops hoistway shaft serving Basement and 3 levels above

Custom size dumbwaiter was designed to suit an

existing 4 stops hoistway shaft serving Basement and 3 levels above

Swing entrances of the dumbwaiter are flushed

with the face of the hall wall provided with flushed hall buttons in

St Steel face plate

Swing entrances of the dumbwaiter are flushed

with the face of the hall wall provided with flushed hall buttons in

St Steel face plate Hall swing doors in open position with fully

enclosed vertical bi-parting car door in closed position

Hall swing doors in open position with fully

enclosed vertical bi-parting car door in closed position Dumbwaiter provided with 1 removable shelf to

enable 2 tier loading.

Dumbwaiter provided with 1 removable shelf to

enable 2 tier loading. Swing type elevator door (provided by others)

and machine room door. Machine room located adjacent to the shaft at

Basement level.

Swing type elevator door (provided by others)

and machine room door. Machine room located adjacent to the shaft at

Basement level. Melamine wall & ceiling elevator car panels.

Wood panel elevator car flooring (provided by others) matching the

lobby floor. Also shown is the hall button in St Steel face plate.

Melamine wall & ceiling elevator car panels.

Wood panel elevator car flooring (provided by others) matching the

lobby floor. Also shown is the hall button in St Steel face plate.

Landing swing doors in open position with

fully enclosed, St steel, automatic & user friendly vertical

bi-folding car door in open position.

Landing swing doors in open position with

fully enclosed, St steel, automatic & user friendly vertical

bi-folding car door in open position. 2 lockable fused disconnects (220 volt & 115

volt) provided in machine room by others.

2 lockable fused disconnects (220 volt & 115

volt) provided in machine room by others. BEFORE: an aging elevator had to be replaced

with a new custom elevator to suit the existing shaft size.

BEFORE: an aging elevator had to be replaced

with a new custom elevator to suit the existing shaft size. Hoistway shaft with wood reinforcement to

support the rail, cylinder other elevator equipment.

Hoistway shaft with wood reinforcement to

support the rail, cylinder other elevator equipment. AFTER : Elevator provided with robust, metal,

perforated accordion car gate.

AFTER : Elevator provided with robust, metal,

perforated accordion car gate. AFTER : Elevator car walls, ceiling, car

operating panel and handrail in St steel. Porcelain flooring to

match the lobby floor by others.

AFTER : Elevator car walls, ceiling, car

operating panel and handrail in St steel. Porcelain flooring to

match the lobby floor by others. Typical concrete pit to endure the elevator

equipment reaction load. 3 sided plywood walls with reinforcement

provided for the rail wall, by others.

Typical concrete pit to endure the elevator

equipment reaction load. 3 sided plywood walls with reinforcement

provided for the rail wall, by others. Hoistway shaft reinforced with LVL planks to

support the rail, hydraulic cylinder, other elevator equipment, by

others.

Hoistway shaft reinforced with LVL planks to

support the rail, hydraulic cylinder, other elevator equipment, by

others. Glass swing door with raised laminate & St

Steel trim on the 2 side elevator car walls with rear glass elevator

car wall.

Glass swing door with raised laminate & St

Steel trim on the 2 side elevator car walls with rear glass elevator

car wall. Metal scissors (beswick) car gate in black

painted finish for that vintage, old charm look.

Metal scissors (beswick) car gate in black

painted finish for that vintage, old charm look.